Takasago Engineering Mexico

Somos un equipo de ingenieros japoneses y mexicanos especializados en ingeniería y construcción con 10 años de experiencia de servicio en el sector industrial y comercial.

Nuestra ejecución de trabajo se realiza conforme a la filosofía japonesa:

Seguridad, innovación, compromiso, tecnología y satisfacción.

Nosotros

Takasago Engineering México es una subsidiaria de Takasago Thermal Engineering.

Presidente

MR. TSUYOSHI MIURA

Capital

10 millones USD

No. de Empleados

50

Establecidos

en noviembre 2014

Filosofía Corporativa

Misión

Nosotros activamos el futuro de la tierra con nuestra revolucionaria innovación ambiental. Takasago sincroniza el aire de los diversos espacios ambientales, creando posibilidades interminables. Cada empleado es parte del orgullo tradicional de la experiencia de construir en estos 100 años de historia de la Compañía, nosotros continuamos el espíritu de expansión de la diversidad y la concreción mediante las relaciones armoniosas con otros. Constantemente somos el paradigma-pionero del cambio de las innovaciones ambientales. Somos capaces de crear el óptimo ambiente espacial no solo de este planeta sino también en el espacio. Estamos profundamente dedicados al bienestar de nuestras familias, colegas, de los seres humanos y de todo tipo de vida en la Tierra.

Visión

Ser un Environment-Creator™

Origen

Contribuir a la sociedad a través de la armonía social y soluciones creativas.

Valores

El TakasagoWay proporciona valor más allá de las expectativas. Actúe con justicia, confianza y orgullo. Generar confianza para crear relaciones duraderas.

Servicios

Especialistas en el sector industrial Diseño y Construcción

Cuarto limpio

HVAC

Eléctrico y control

Sistema de Utilidades

Panel Solar

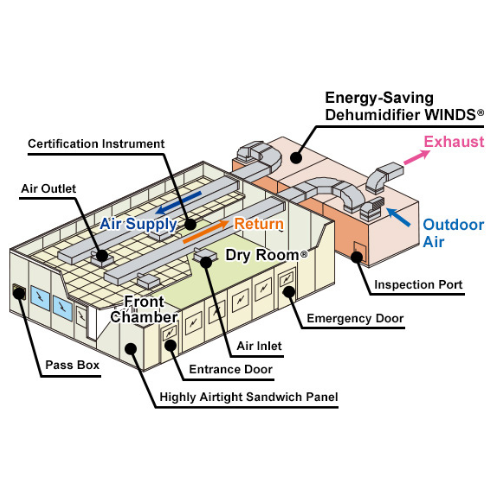

Cuarto seco

Carbono Neutral

Sala Limpia Biológica

Sistema de Protección contra Incendios

Takasago Technology

Takasago Technology

Takasago Energy

Optimization for IDC data centers with Green Air IDC

Watch our IDC difuser system in action

¿Por qué elegirnos?

- Salas Limpias, Salas escas y HVAC

- Ingeniería conceptual e ingeniería de detalle.

- Análisis energéticos

- Proyectos arquitectónicos de ingeniería

- Coordinación e Integración de servicios de ingeniería

- Supervisión de obra

- Ejecución de obra

- Contratación general

- Planificación mensual de la construcción.

- Seguridad e Higiene

- Programación de Trabajo y Tareas Simultáneas

- Coordinación de trabajo en equipo

- Monitoreo de comunicaciones

- Gestión de presupuestos

- Auditorías y Control de Calidad

- Pruebas y puesta en marcha

- Postventa y Mantenimiento

- Diseño conceptual

- Renderizado 3D

- CAD arquitectónico

- Ejecutivo

- Instalaciones eléctricas

- Sistemas HVAC

- Instalaciones de plomería

- Diagramas de utilidad

- CCTV IP

Haz clic para visitar nuestras oficina

Todos los derechos reservados.

Winner of the 7th “Environmental and Equipment Design Award”

Winner of the 7th “Environmental and Equipment Design Award”